Bamboo Fly Rod Building

|

LINKING THE PIECES

Linking the pieces of bamboo fly rod

EXCERPTS CHAPTER VII

The most widely used assembly system for fly rods is made with ferrules. It is a proven system, despite some drawbacks, especially because of its wearing characteristics; something that can however be easily remedied.

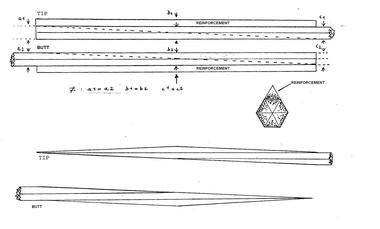

7-3 Principle scheme of the bevel

Two other criticisms of the ferrule are its weight that is not negligible and the bending curve change as a stiffer area is introduced. Although hardly noticeable, this defect greatly affects the action, even if the ferrule was part of the profile calculation.

The idea of a spliced assembly or direct assembly is very ancient and was used by the salmon fishers for ages and this assembly was tied with a yarn.

This technique has totally fallen into disuse, which is extremely regrettable as the direct assembly is the best one when it comes to the rod action and it is the sturdiest in every case. The comparison between two rods having the same profile but different assembly modes (ferrule or direct) shows beyond doubt the advantage of the direct spliced assembly. One feels that the rod assembled this way is 15 centimetres longer whilst being lighter.

(…)

The reinforcement is made to counteract the weakening caused by the bevel cut in the way the rod is working. We will see later that by gradually diminishing the reinforcement, one will obtain the most even bending curve available, making sense of this assembly process. The bevel length depends on the piece thickness put in the splice cutting tool; generally 13 centimetres for a thickness of 5.5 millimetres (between faces).

7.8 Finished bevel with its protective device. The joint between the polyurethane varnish and the epoxy varnish is under the ligature on the left

The part that will receive the adhesive tape will be varnished with epoxy (a thin coat applied with the finger) as a standard varnish (polyurethane for example) gradually peels with the adhesive tape (see the corresponding chapter). For the assembly during fishing parties, we use a translucent adhesive tape (12 mm wide Scotch 550) which is wound on a specially made hard wood reel. (Photo 7-9).

7.10 Spliced assembly adjusted with its adhesive tape. Note the tiny adjustment mark in the centre of the fitting.

(…)

SPIGOT ASSEMBLY

7-13 Spigots on a three pieces salmon rod

By 1982,

during conversations with the painter Jean-Claude Scheaffer and then with Claude Bodier, we were going over the advantages and drawbacks of the ferrules and the direct assembly when the idea sprang up.

Why don't we drill the scion and the butt and make a carbon fibre fitting?

(…)

FERRULES

Some French home-builders have nevertheless made titanium ferrules that are quite light and give high performance. The weight saving is significant: for a 6.5 mm diameter ferrule the difference is between 9 grams for the nickel silver and one to 4 grams for the titanium one.

Nevertheless you must pay attention as the titanium as a tendency to seize up and here once again the paraffin wax is very useful (Photo 7-16).

7.16 Titanium ferrules.

(...)

Other well equipped home builders designed and made nickel silver ferrules as good as the American ones and these can be of a different diameters to the bamboo as with the American "Super Z".

(...)

Bamboo fly rod building ©2010