Bamboo Fly Rod Building

The final planing

The final cutting for building a bamboo fly rod

EXCERPTS CHAPTER IV

The triangular rough strips should at this point all have the same cross section, and the final planing is intended to bring them all to the required shape. We will then have six strips which, … (...)

THE FINAL PLANING FORM

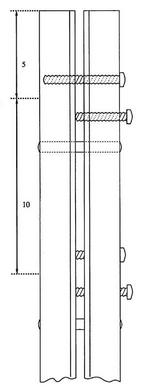

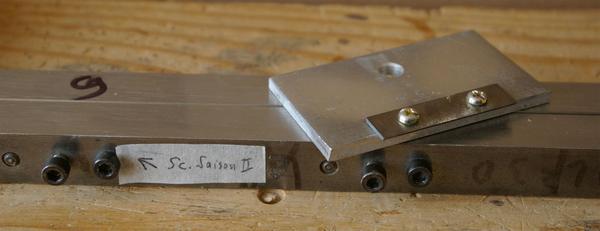

The final planing form consists of two metal bars tied together with sliding alignment pins and having screw adjustments to enable the gap between the bars to be set at the desired distance.

Each bar has a 30 degree. chamfer from the vertical axis on the inner side. The two chamfers form a 60 degree groove defining two sides of an equilateral triangle ...(...)

Building the planing form

You start with two rolled mild steel bars 1.5 meters long with a 20 X 20 mm cross section. Every 10 centimetres a floating alignment pin links the two bars together along with an adjustment bolt and a locking bolt in order to firmly set the space between the bars.

The first pin / bolt alignment set will be placed at 5cm. from the form end, followed by another at 15cm. the third at 25 cm and so on. ...(...)

The process is as follows :

- The two bars must first be accurately aligned and clamped together. Then, after marking the desired locations of the holes with a centre punch commence drilling the first alignment pin hole through the centre of the two bars using a drill press. The hole should first be drilled to 5.8 mm. diameter and then enlarged to 6 mm with a reamer (if you don't have one use a 6 mm precision bit). Then insert the first 6 mm diameter alignment pin.

- Then continue drilling ...(...)

Chamfering

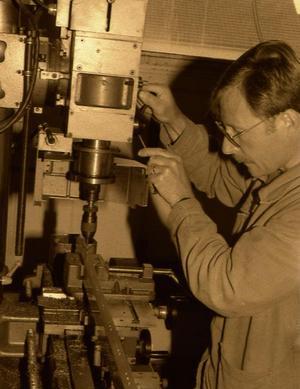

There are high precision milling machines that can be used for cutting the chamfer but the beds are often not long enough to mill 1.50 metres in one stroke. This could prove to be a difficult problem to overcome ...(...)

The Chamfering tool

(...)

So, following Daniel Brémond's advice, I decided to mill the chamfers in my planing forms myself. The process is quite simple although it is time consuming as the form material ...(...)

(...)

ADJUSTING THE FORMS

The depth gauge

4.7 The depth gauge upon the form.

The dial indicates 6.10, that is to say 3.9 mm of depth

For a number of years I have used a depth gauge made from a dial gauge. It was easy to make two accessories and thus obtain a depth gauge. First I made a metal base ...(...)(…)

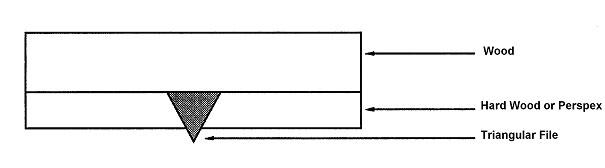

THE STRIP CUTTING : PLANE, FILE AND SCRAPER

After having exclusively used the various planing processes, I had to conclude that there is not a problem of choice but tool compatibility.

For the very thin tip ends (strips with a thickness of 0.6 to 1 millimetre) be careful not to break the strip by pressing too much on the scraper or scraping at too steep an angle.

Cutting technique

Proceed as follow: place the triangular rough strip, so that only 20 centimetres are inside the form, (this will be the smaller end of the strip in the end) and secure it with a quick-release clamp and, a wood block covered in foam to protect the the surface of the strip. (photo 4.10). Plane, file and/or scrape everything protruding above the form between two adjacent adjustment sets ...(…)

Rods assembled by bamboo ferrules

It is at that stage that the male bamboo ferrule must be prepared if one want to make a rod assembled by bamboo ferrules.

For the creation of the bamboo ferrule please see chapter VII.

4.9 A scraper (carbon steel blade) fitted with an aluminium handle.

Note the mark indicating the exact place of a tip head for a 3.65 m salmon rod.

For the very thin tip tips (strip with a thickness of 0.6 to 1 millimetre) be careful not to break the strip by pressing too much on the scraper angle.

Bamboo fly rod building ©2010