Bamboo Fly Rod Building

EXCERPTS CHAPTER V

Hollow building bamboo fly rod

LIGHTENING

When examining a bamboo culm, one notes that when going toward the centre, the power fibre density becomes lower, as one moves inward into the pith. As the fibre density becomes less so does the bamboo stiffness.

One could consider removing the "weak" fibres, or pith, along the entire strip interior whilst keeping only the "stronger" exterior fibres (power fibres). However, I don't believe that this approach would justify (...)

ARGUMENTS IN FAVOUR OF LIGHTENING

5.1 Principle of lightening

The major drawback of the bamboo rod, "its original sin", is its mass.

"Too heavy, too heavy", that is the outcry of the fishermen's "vox populi".

But the "vox populi" is not "vox dei". While the perceived mass of a rod is its weight at the static balance point, its real weight is what you feel in your hand when you use it.

I know that there are some carbon fibre rods that feel, …

(...)

Hollowing process

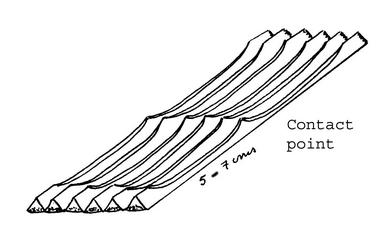

The planed strips are placed side-by-side; enamel face down, on a flat board. They are then secured by three or four transverse adhesive strips. The adhesive tape is the type used for paint masking as the adhesive used for carpets tape is too strong. It is this layout that will be followed for gluing. (...)

Small strips of wood covered with foam to protect the bamboo are arranged with clamps which lock the strips on each side of the area you are hollowing These are removed following the hollowing process (Photo 5.4). Previously, when I didn't hollow at the nodes, the distances between the nodes were divided by two, so I had cells between 5 to 6 centimetres, with contact points of 2 millimetres … (...)

The strips are now ready to be glued and assembled (Photos 5.3, 5.4 and 5.5).

Hollowing the strips causes a reduction of the surface area to be glued as most of the meeting surfaces remaining are the thicknesses of the sides of the strips.

Using a polyurethane glue, which expands inside the cells, thus increasing the glue surface area is therefore very useful.

Bamboo fly rod building ©2010